Lepower Shares: flip light source series of new sword out of the sheath

2016-05-05

Part1: Witness the journey, we have come all the way

The development of LED packaging has experienced from in-line DIP packaging to TOP SMD packaging, and then to integrated COB packaging and chip-level CSP packaging. With the deepening of high-power LED applications in semiconductor lighting, LED packaging technology is becoming more and more high-power and integrated.

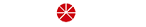

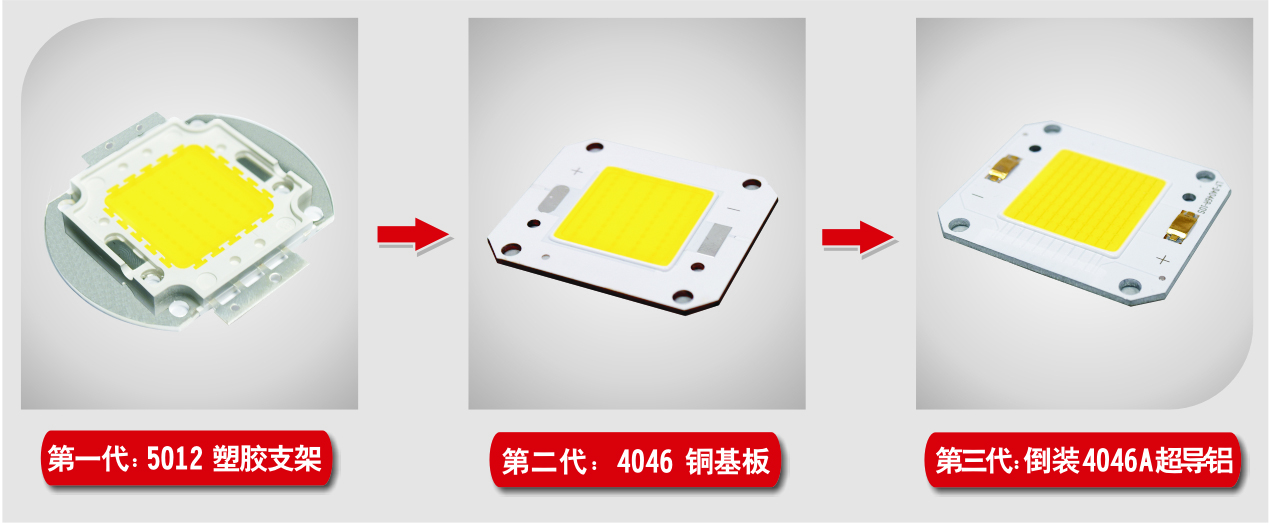

For LED packaging products, packaging materials and packaging structure are the main factors affecting their performance. Since Liyang set foot in the field of LED high-power light source in 2008, the products have undergone three major changes. In terms of integrated light source, from the earliest 5012 injection bracket light source, to 4046 copper plate light source, and now F4046 flip light source; Time after time performance improvement, time after time technological change, so that the advantages of Liyang shares in the field of integrated LED light source are gradually recognized by the industry. In terms of high-power lamp beads, Liyang Shares from the earliest 1-3W imitation current lamp beads, to SMD3030 lamp beads, and now flip FE30/FE35 lamp beads, the chip of the product is getting smaller and smaller, the reliability is getting better and better, the weather resistance is getting stronger and stronger, and the cost performance is getting higher and higher. Along the way, Liyang Shares have witnessed the transformation and technological innovation of LED light source products.

Prart2: Keep up the pace and experience disruptive innovation

As a company focusing on LED high-power light source products, Liyang has been committed to actively improve the product cost performance, invest a lot of R & D resources, focusing on the research and development and production of flip light source field, at present, Liyang stock flip light source series products have been significantly better than the same performance formal products in product performance and cost performance. Is gradually changing the long-term customer understanding of inversion: high price, unstable process.

At present, the mainstream packaging forms of LED chips on the market mainly include SMD and COB packaging, and the packaging materials are mainly divided into EMC, PPA\PCT, metal-PCB and ceramic materials. The flip COB series is based on the superconducting thermal ALC aluminum substrate and is equipped with flip chips to achieve a new packaged COB structure. This is a major change to the traditional COB structure, which greatly reduces the thermal resistance of the product, the thermal conductivity of the light source is better and the light is higher, and the heat dissipation structure of the lamp is optimized to save the cost of the lamp for customers.

Liyang Stock flip EMC series, using imported EMC bracket, the use of international advanced 3D automatic printing technology, to achieve flip chip packaging. The application of flip-chip in EMC support platform breaks the tradition, changes the traditional formal wiring mode to the non-gold wire flip-flop mode, and introduces the international first-class fully automated production line, realizing the advantages of high production efficiency, low device cost, high reliability, long service life, simple application and so on.

One small step, one big step

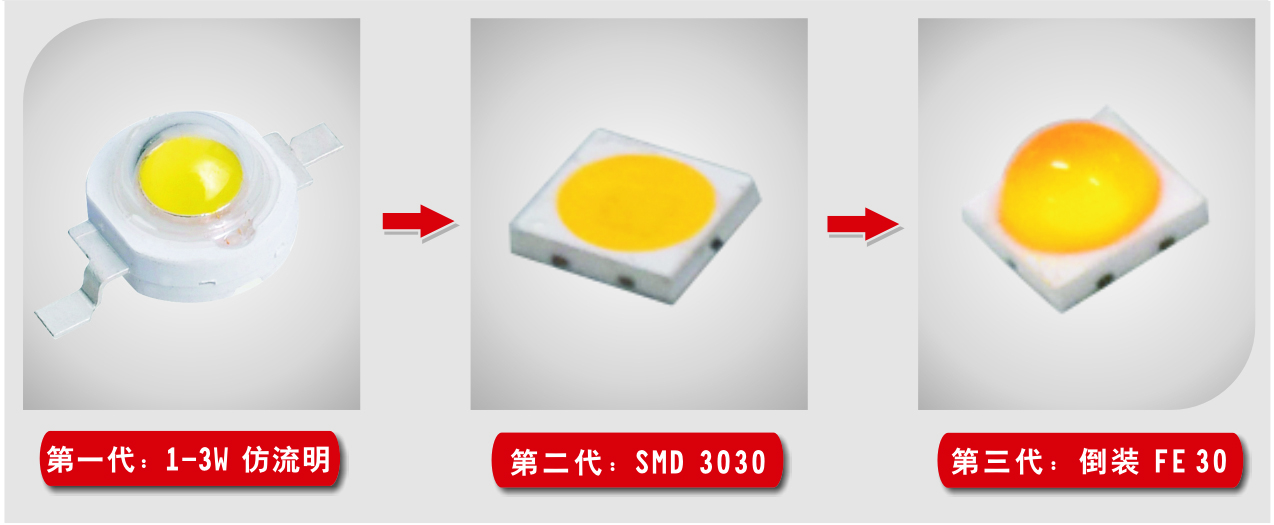

The traditional high-power device chip electrode is located on the luminous surface, and the bonded gold wire is located above the luminous surface, which blocks the light from the chip and reduces the luminous efficiency of the LED. The flip-chip electrode used in the flip-chip products is located at the bottom of the chip, which does not affect the surface light; The packaging without gold wire directly avoids the absorption of light by gold wire, and the light output efficiency is higher.

Streamline administration and improve efficiency

The traditional high-power device bond alloy wire is more prone to problems such as welding, surge impact, insufficient resistance to high current, and stress fracture caused by thermal mismatch with packaging adhesive, which is one of the weakest links in the reliability of LED devices. The flip product reduces the welding process, improves the production efficiency, and completely eliminates various reliability problems caused by the bonding alloy wire.

Change the connection mode, from quantitative change to qualitative change

Traditional high-power devices generally use insulation adhesive crystal, insulation adhesive thermal conductivity is low, become the heat transfer bottleneck between the chip and the support, affecting LED heat dissipation and long-term reliability. The solder material with thermal conductivity tens of times that of insulating glue is used to realize the thermal, electrical and structural interconnection between the wafer electrode and the bracket, which not only improves the bonding strength of the product wafer and the bracket, but also greatly reduces the packaging thermal resistance of the LED, improves the thermal conductivity of the LED, and greatly improves the reliability and life of the product.

Prart3: Seize the opportunity, one step ahead of others

Flip LED subverts the traditional LED process, from the chip to the package, requiring higher equipment investment costs. In terms of flip LED packaging, solder paste printing requirements are accurate, reflow requirements are higher, the precision requirements of LED solidification machine are also higher, and professional flip detection needs to be increased. At present, Liyang flip LED production line has been smooth mass production, and the introduction of various products, for the company's future development to win the opportunity.

The flip products of Liyang shares have been widely used in automotive lighting, outdoor lighting and other fields, promising prospects, and will soon replace the traditional LED light source products are widely used in aviation communications, commercial and civil lighting, urban lighting engineering, road lighting and many other fields.

The following Liyang shares will launch detailed product series reports, please pay attention!